BMW was unveiled to much fanfare at the 2021 Munich International Motor Show the iVision Circular concept car, designed for ‘the circular economy’, an eco-movement buzzword for recycling old stuff into new stuff with minimal energy. The iVision was the model of what the future of cars could look like, except for one thing. It couldn’t move unless it was pushed, pulled or pulled onto a trailer. There was no engine in it.

Yet BMW could rightly have called iVision a conceptual breakthrough, except for one other thing. A group of students from Eindhoven University in the Netherlands were the first to do it in 2018, and did it even better. Their car made of recyclable materials – the composite chassis was largely derived from sugar beets – could travel 400 kilometers on a charge and reach top speeds of around 100 km/h.

Since 2013, Eindhoven students have been building operational concept cars virtually every year to prove that eco-friendly design is within the reach of major manufacturers if they would just try (yes, you detect a hint of cheerful shame; the students tend to go all out go Greta Thunberg with eco-enthusiasm).

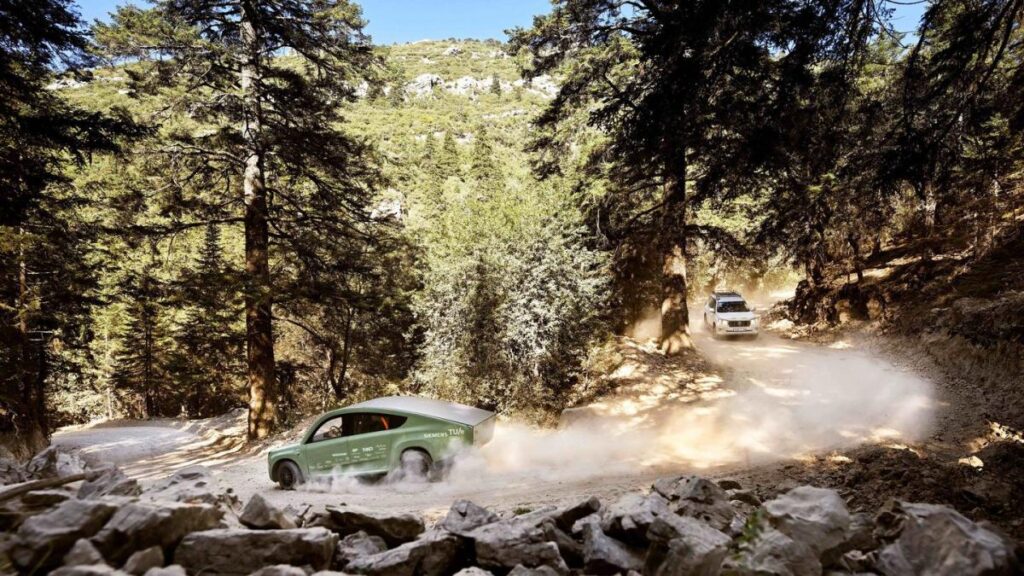

Its latest achievement, a two-seater all-terrain camper called Stella Terra, completed a 620-mile on- and off-road journey through Morocco to the Sahara, powered entirely by onboard solar panels. Terra, as the students call it, claims to be a first, has a theoretical top speed of 150 km/h and a range of 700 kilometers (when it’s sunny).

The secret of its success is the uniquely efficient integration of off-the-shelf components, computer programming, a custom energy management system and 22 high-caffeine students.

The students come up with their own projects, from cars to drones and medical devices. Success is not a given, said Madis Talmar, a professor who oversees the student programs. But the car projects “have succeeded nine times so far,” he said, “and that’s a miracle.”

Two Eindhoven teams focus mainly on passenger cars, TU/Ecomotive, which has produced a car from recycled waste, a car that can drive 400 kilometers on the energy equivalent of a liter of gasoline, and one that is largely forged on a 3D printer . Then there is the Solar Team Eindhoven, which has so far designed sun-powered cars to participate in the Australian World Solar Challenge, a 3000 kilometer race. Eindhoven won its class in four consecutive challenges.

Last year, Solar Team Eindhoven felt that there was nothing to prove by going back to racing. Instead, it would build a utility vehicle, a solar-powered off-road camper, and prove itself to be both on- and off-road worthy. “That is the story we want to tell,” says Thieme Bosman, PR manager of the project. “That this is now possible.” Take that, Detroit.

For an entire year, team members suspend their studies (still paying tuition) and spend days and nights in front of computers, in meetings, consulting with manufacturers and startups. Housed in a small garage, they worked in secret, usually working 12- to 16-hour days, eventually requiring a day and night shift to complete construction.

Project teams start recruiting students at student orientation, looking for future engineers in software, thermal dynamics, aerodynamics, structure and electricity, as well as specialists in design, finance, PR and event marketing. Those skills are secondary to studying quickly and being sympathetic. “It’s not: ‘We know someone who can do this (one thing) very well’, but someone who can learn quickly and fits in well with the team,” said Bosman, who had set his sights on building a solar car. back in primary school.

Projects start with a clean slate. “We knew we would do something with the power of the sun and mobility,” but that was the only limitation, Bosman said. Early ideas included several solar cars, solar-powered tuk-tuks and a solar-powered submarine, which was dismissed as impractical. The solar-powered off-road camper got the nod.

But how should you build it? The starting point was to minimize energy consumption. Weight saving was the top priority. Reducing rolling and wind resistance was crucial when replacing side mirrors with small cameras. The back of a pop-up camper created enough space for two sleeping bags (where broken students occasionally napped during construction), but closed it off to avoid drag along the way.

Hub motors were chosen because they were lighter and more efficient than a single motor and drivetrain layout. But four-wheel drive or two? It was an off-roader after all. All-wheel drive might get a car out of the swamp, they reasoned, but a lighter car might not get stuck in the first place. Having two motors at the front would save money, allow shorter cable lengths, save weight and reduce electrical transmission losses. It was two engines.

Students have innovated lightweight parts. For example, the dense battery firewall was replaced with a honeycomb sandwiched between two aluminum plates treated with an advanced fire-resistant coating. It was tested for safety by an external laboratory because “we were not able to make such a big fire at our home,” says Bob van Ginkel, technical manager of the project.

The solar cells posed special challenges. The most efficient panels, made for the space, were too expensive. More efficient cells produce less current and are usually protected by heavy, inflexible glass. The students solved the problem with panels with a new film coating, creating a lightweight protective barrier that also captured more light than glass. The coated cells remained flexible so they could conform to the car’s aerodynamic roof and hood.

The bigger problem with the panels was maximizing power to the batteries. Batteries charge best with a consistent power supply, which solar cells cannot provide. Many variables cause cell power to fluctuate: temperature and passing clouds, to name two. It requires a system that manages how the solar energy is distributed.

Off-the-shelf energy management systems were either too large or could not handle the 400 volts of the panels. “So we designed it all by ourselves,” says van Ginkel.

The resulting half-pound of 7.9-by-7.9-inch printed circuit boards were 97 percent efficient, equal to the best of the larger residential converters. It would later prove so efficient that the car’s regenerative brakes sometimes had to be reversed because the battery was too full to charge.

The production was a process of trial and error, causing both elation and fear. “A very big moment was when the engine turned over for the first time,” said van Ginkel. On that day, the team met anxiously, not quite sure what to expect from the patchwork system. They held their collective breath as the accelerator pedal was pressed gently, there was a low hum, the engines revved, and a triumphant cheer erupted. “If it worked outside the car,” van Ginkel said, “it will work inside the car.”

When the almost complete Terra was finally rolled out for the first test drive, the mood was festive and confidence was high. “It was indeed like launching a ship,” said Van Ginkel. When the accelerator was pressed, the engines whirred, the wheels turned, and as expected, Terra moved, but backwards. The room fell into an aggrieved silence. “After about ten seconds we burst out laughing,” said Van Ginkel. The motors have been swapped from left to right, problem solved.

The completed Terra still needed a testing ground. “How do you prove that an off-roader can run on solar energy?” Bosman said. They chose Morocco because it was not difficult to ship Terra there. Secondly: “Every few hundred kilometers there is a different landscape,” says Bosman. “And sun.” The goal was to drive more than 900 kilometers from Tangier to the Sahara in ten days, entirely on solar energy.

The sun was plentiful, but so were the wheel-bending potholes. The team was faced with manageable technical problems to solve every day, but nothing was as intimidating as the potholes. Within days, the road ruts had broken a knuckle on the steering gear, which, with some scrambling, they were able to repair.

Then a strategy emerged. An advance car radioed back to warn Terra of approaching dangers. But on the fifth day the inevitable happened. The wheel ended up in a hole and the steering rod broke like a stale syrup waffle.

Unable to make the repairs with the equipment on hand, the students sat deflated on the side of the road. After nine ‘wonder years’ of successful concept cars, and following a scornful withdrawal from the Australian competition, where it was the odds-on favourite, the Eindhoven Solar team was positioned to make history as the car programme’s first major failure. “When we had to trailer the car to the accommodation,” says Bosman, “it really had an effect on the team dynamics and team spirit.”

Disheartened but unwilling to give up, the students set to work with all hands on deck. The CAD engineering team designed a reinforced steering mechanism. Coincidentally, the next day a videographer came from Eindhoven to meet the team. The videographer could bring a replacement part if he could have it made immediately. A panicked call was made to a Dutch manufacturer who agreed to CNC mill the redesigned tie rod overnight.

The miracle was miraculously intact. The team later calculated that they had enough battery power in reserve to drive 30 miles (48 kilometers) back to the scene of the failure and resume the route uninterrupted.

After the tie-rod drama, the quiet last five days almost seem like an anticlimax. And yet, when the students reached the Sahara, a year of late nights, fears, near failures and an eventual success erupted into a spontaneous riot of joy, with students pouring sand on each other, summer skipping through the dunes, hugging each other and did cartwheels. , screaming and taking turns flooring Terra across the sand like a dune buggy.

One last ritual was held. Solar races always ended with a jump into a fountain or an ocean. So at the hotel, the students joined forces and jumped into the pool fully clothed. It was not possible to wash away all the sand. “A week later,” van Ginkel said, “I could still find sand in places where I didn’t think there could be sand.”

You might also like it