For over 35 years, Chinese manufacturer Advance Denim has strived to revolutionize vintage denim styles through innovation.

This drive for progress has resulted in over 40 patented technologies in the past two years. Each innovation addresses performance and sustainability challenges while improving the denim production process.

More from Sourcing Journal

One of these recent developments is FitSense® Denim, a breakthrough denim that allows designers to customize stretch levels in specific areas for optimal comfort and shaping. By combining advanced fiber technology, enhanced fabric construction and innovative garment finishing, it seamlessly integrates stretch and shaping zones, making them virtually invisible on the surface of the fabric, according to Mark Ix, director of North American marketing for Advance Denim.

Another development that Advance Denim has recently implemented is FreeCross Bi-Stretch. This allows denim to be stretched in both the warp and weft threads.

“Free Cross Bi-Stretch technology creates a truly vintage aesthetic,” said Ix. “With improved performance, it truly addresses the inconsistencies of traditional bi-stretch fabrics.”

Sustainable growth

In line with its commitment to continuous improvement, Advance Denim also sets ambitious goals each year to improve both sustainability and efficiency. The denim factory’s focus extends beyond cutting-edge denim innovations to include creating a production system that is both efficient and sustainable.

A good example of this is Bigbox painting, where water consumption is drastically reduced by up to 95 percent by combining the traditional eight to thirteen paint boxes into one box.

Meanwhile, Advance Denim’s Blue Loop Indigo Recovery System, already implemented in China, uses membrane separation to remove unused indigo, resulting in clean water and reusable indigo with a recovery rate of 98 percent for both. Scheduled for implementation in 2025 at Advance Sico, an Advance Denim facility based in Nha Trang Vietnam established to better serve its customers and diversify its production base, this system will significantly improve the circularity of the dyeing process.

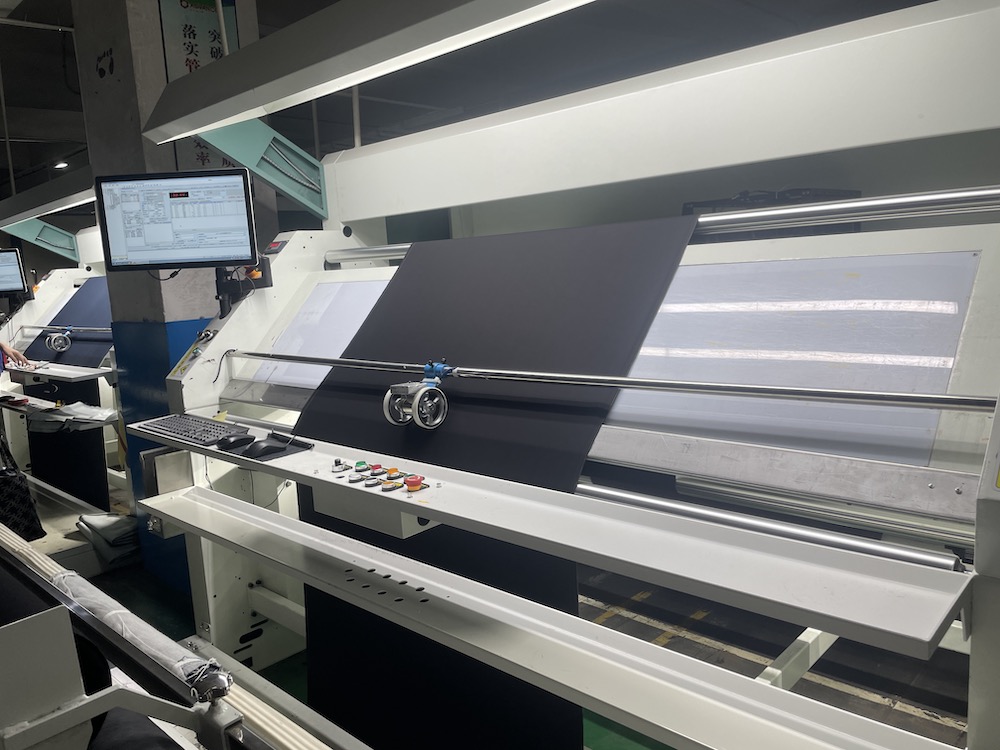

In addition to advances in dyeing technology, Advance Denim is also leading the way in production efficiency innovations with its Artificial Intelligence (AI) inspection system.

Traditionally, denim inspection relies on human eyes to detect fabric defects, a process that is prone to errors, Ix noted. By training AI software with more than 3 million denim images, Advance Denim is the first in the industry to achieve greater than 97 percent accuracy for fabric inspection. This AI system will not only refine the inspection process within the factory, but when integrated with AI systems at apparel manufacturing partners, will further improve speed and accuracy, potentially reducing the need for multiple inspections and reducing fabric waste.

“Advance Denim prides itself on being at the forefront of both fabric design and sustainable manufacturing,” said Ix. “By pushing the boundaries of what’s possible, the company remains committed to becoming the highest quality, most sustainable denim factory.”

More information about Advance Denim Limited here.