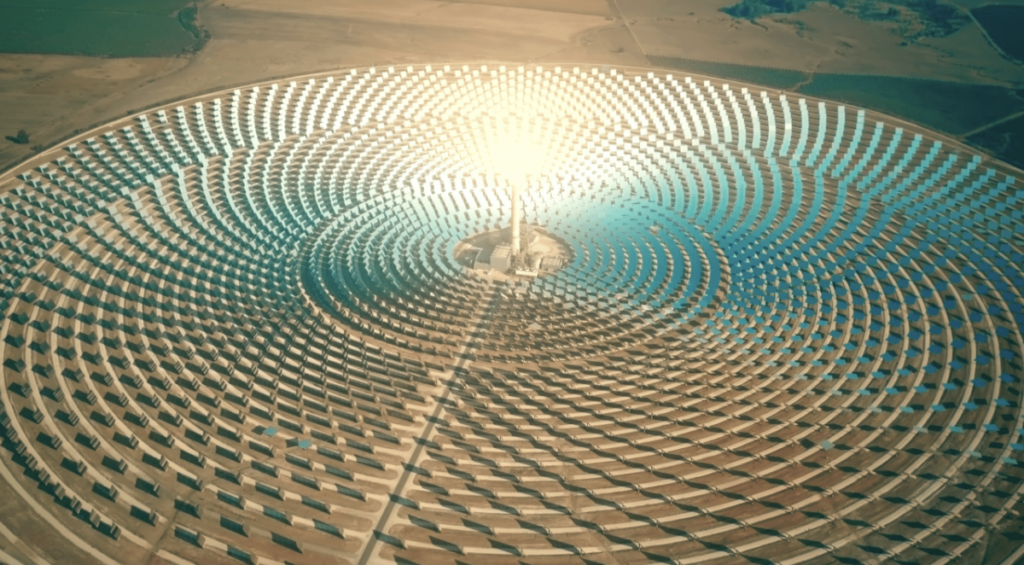

A large concentrated solar power (CSP) project in China has selected Sulzer, a global fluid technology company, to supply both the hot and cold molten salt pumps for the facility. The planned 100-MW solar project will feature technology designed to deliver electricity from solar energy 24 hours a day. Molten salts have been used in the nuclear industry for nearly 70 years, and Sulzer has been involved in the design and manufacture of the pumps that transport the high-temperature fluids around the cooling circuits. The company was involved in pioneering the technology for use in the solar industry more than 15 years ago, allowing thermal energy to be stored overnight. (caption id=”attachment_220758″ align=”alignnone” width=”640″)

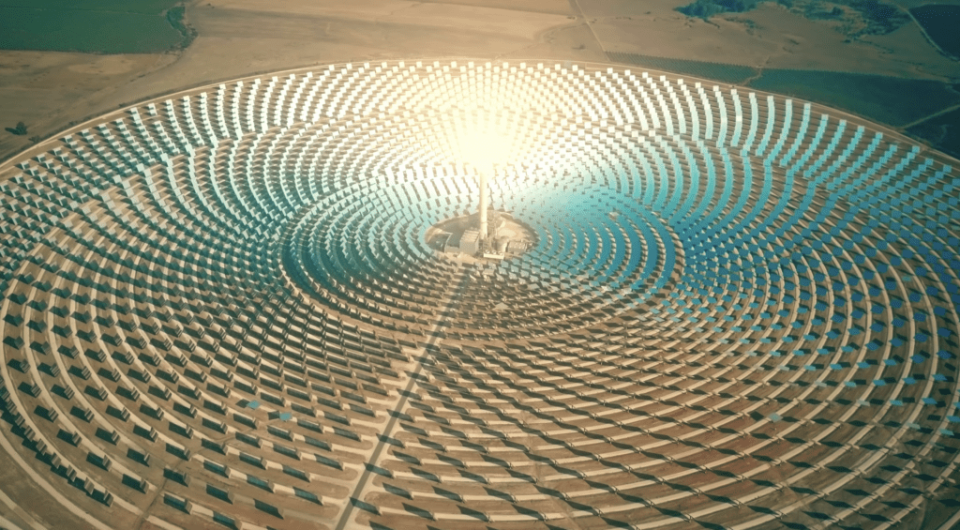

A large concentrated solar power (CSP) tower project in China has selected Sulzer to supply both the hot and cold molten salt pumps. Source: Shutterstock(/caption) Molten salt is pumped into solar collectors (towers or parabolic mirror fields), where the temperature rises from approximately 300C to 600C. The high-temperature salt is then stored in a tank and transferred to a heat exchanger, where the thermal energy is used to create steam that generates power using a turbine/generator. This circuit acts as a thermal battery, allowing solar plants to provide power 24 hours a day when solar conditions are good. Sulzer has a track record of supplying hot and cold molten salt pumps to solar plants around the world, including recent projects in China. The 100-MW CSP Tower project is the first of its kind to use Sulzer pumps for both the hot and cold circuits. The three cold molten salt pumps will be equipped with 2.6-MW motors and will extend 18 meters below the baseplate into the cold molten salt tank. These are combined with two hot pumps, with all pumps being manufactured at Sulzer’s Suzhou plant in China, Jiangsu Province. The biggest challenge in this project was the increased operating pressure required in the molten salt circuits. Sites with smaller outputs normally operate at around 50 bar, but this project required a pump feed pressure of 100 bar. (caption id=”attachment_220757″ align=”alignnone” width=”640″)

Sulzer has a long track record of supplying hot and cold molten salt pumps to solar installations around the world, including recent projects in China. Source: Sulzer(/caption) Each pump is built to order and this project had to be designed to take into account the increased pressure and slightly higher power requirements. Compared to more common lower pressure pumps, there are several critical points, such as the design of the throttle bushing and bushing bearing, that need to be carefully assessed, correctly designed and tested before the manufacturing process can begin. In this case, the end user wanted to achieve certain objectives when delivering this project. They wanted international brands to supply the key equipment, which would ideally be manufactured in China and be cost-effective compared to the competition. Sulzer said that the engineering of the bare shaft pump will be completed in Europe and that production will be a close collaboration between facilities in Belgium and China. In addition, the company will offer a comprehensive support package for the products supplied through the local service centre. By selecting Sulzer for both the hot and cold pumps, the end user can also streamline their spare parts inventory. As part of the contract, Sulzer’s local engineers will be on hand to support the installation and commissioning of the equipment. Due to their length, the pumps are being assembled on site before being installed in the storage tanks. This installation follows several other successful projects in China for Sulzer, including three hot pumps for another 100-MW CSP, and six hot and five cold pumps for a 42-MW parabolic trough plant. —CURRENT edited this content, which was contributed by Sulzer And DMA Europethe company’s marketing agency.