Italian clothing brand OVS is expanding its partnership with Swiss product tracing company Haelixa.

For the second year, OVS will use Haelixa’s DNA marking technology to trace cotton cultivation in Italy.

More from Sourcing Journal

The collaboration is an important part of OVS Cotone Italiano, the retailer’s mission to support domestic cotton cultivation. OVS sources long-fiber, high-resistance cotton from Palermo, Sicily. Haelixa’s patented marker is applied to the cotton at the gin near the farm to record the “fingerprint” of the raw material.

The fibres are tested throughout the production process, so we can guarantee that the cotton used in this OVS collection is ethically and sustainably sourced.

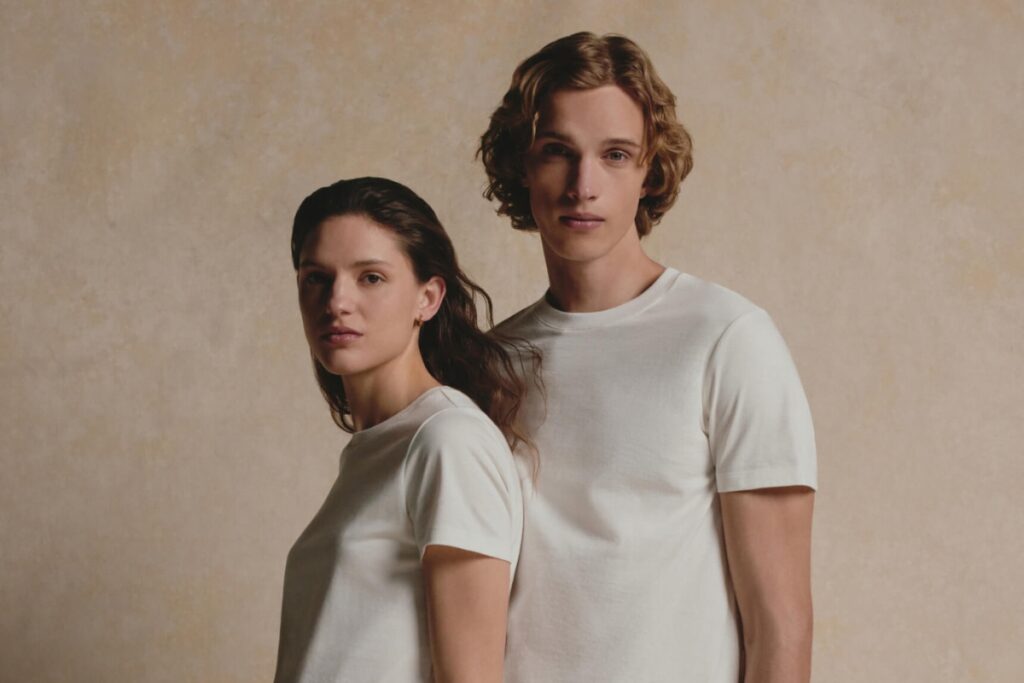

OVS introduced a collection of T-shirts made from cotton last April. Simone Colombo, head of corporate sustainability at OVS, said the company’s goal is to source 5 percent of its cotton needs from Italian farmers within a few years.

By working together with Haelixa, OVS meets the demand and sets a new standard for cotton in Italy. The alliance benefits customers and farmers in Italy, as they receive fair recognition for their work.

“By tracing the journey of the cotton grown in Italy, we support OVS in bringing full transparency to their supply chain,” said Patrick Strumpf, CEO of Haelixa. “The marking increases trust in the brand and enables OVS to make sustainable product claims.”

OVS is working to improve the social and environmental impact of its products. Since 2019, 100 percent of its denim is made without potassium permanganate. Instead, OVS uses worker-safe treatments, such as laser technology or biodegradable enzymes, to create the distressed denim effect.

Last year, the brand partnered with “The Godfather of Denim” Adriano Goldschmied to design an elevated denim collection featuring sustainable technologies. The key innovation was the introduction of Blue InfinityPakistani mill company Half Moon Bahuman‘s dyeing process that delivers up to 62 percent water savings compared to conventional indigo dyeing methods, as well as significant reductions in energy consumption and CO2 emissions.